- Show results for

- Share

What Is Autoclaving? How Does an Autoclave Work? Microlit Autoclavable Products

Resource Description

Contents

What Is Autoclaving?

Liquid handling products as well as other laboratory equipment need to be sterilized so that harmful bacteria, fungi, viruses, etc. are killed. How can this be done? One of the best and most effective ways is autoclaving. Essentially, autoclave sterilization is using steam at high pressure to clean and remove all bacteria from objects. What is an autoclave? It is a heated chamber used for this sterilizing process.

Note that you CAN’T autoclave acids, flammable & explosive materials, corrosive, reactive, or toxic materials, chlorine-based/chlorine-included products, radioactive materials, etc.

Autoclave: Working Principle

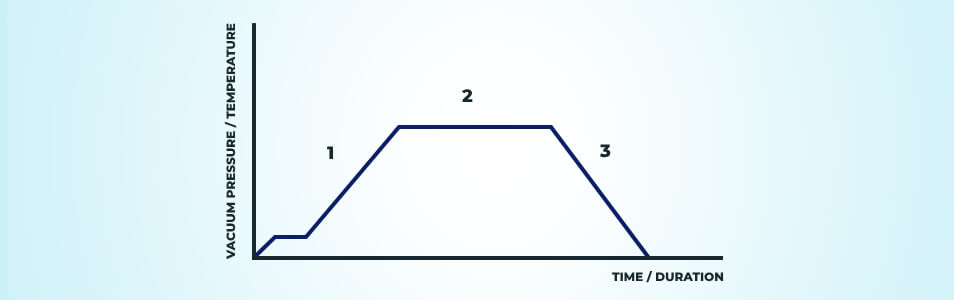

How does an autoclave work? The autoclave operation includes three phases.

Phase 1: Purge

The air is removed from the chamber. The vacuum system in the autoclave is made to replace the air with steam in the sealed chamber.

Phase 2: Exposure

Once the air is removed, the sterilizer drain closes. The steam is continuously admitted in the chamber. As a result, the increment of pressure & temperature inside the chamber is at the desired level. During the exposure phase, the laboratory equipment is held at the sterilization temperature for a certain amount of time.

Phase 3: Exhaust

Pressure is released from the chamber via the exhaust valve, returning the interior to ambient pressure.

Microlit Autoclavable Products

Microlit has decades of experience and expertise when it comes to reliable liquid handling products, it offers a wide range of autoclavable liquid handling equipment, for example, micropipettes and bottle top dispensers.

Here are a few popular products. They are fully autoclavable at 121°C (249.8°F) & 15 psi for a duration of 10-15 minutes.

Microlit SCI-100 Scitus Bottle Top Dispenser (10-100ml)

This bottle top dispenser has high precision as well as chemical compatibility for organic/inorganic chemicals. It can be used to dispense solvents, corrosive acids, and also other reagents in various lab environments (healthcare institutions, research institutes, the food & beverage industry, and so on).

BENEFITS

- EasyKnob Volume Adjustment Knob (for effortless volume change, 180-degree rotation)

- PTFE Piston (for smooth movement)

- Springless Valve (for jam-free operation)

- FlexiNozzle Adjustable Delivery Nozzle (for easy dispensing)

- 360-degree Adapter (for more flexibility)

Microlit LNT-HF-10 Lentus Bottle Top Dispenser (1-10ml)

This bottle top dispenser is made to accurately and safely dispense such highly aggressive chemicals as Hydrofluoric acid.

BENEFITS

- EasyKnob (volume adjustment knob, 180-degree rotation)

- PTFE Piston (for trouble-free movement)

- Recirculation Valve (for liquid redirection)

- Springless Valve (no jams)

- FlexiNozzle (adjustable delivery nozzle)

- 360° Adapter (for unmatched flexibility)

- ISO 8655 Conformed Calibration

Before autoclaving a bottle top dispenser, separate the piston from the assembly. After that, you can sterilize the housing & piston independently.

Final Thoughts

Autoclaving is an effective way of making laboratory equipment and medical instruments sterile. This process has three stages (purge, exposure, and exhaust). Autoclaves are used in various applications.

Before autoclaving, make sure that your equipment/instrument is autoclavable.

On Prime Lab Med, there is a broad range of autoclavable products. Microlit offers best-in-class liquid handling products, including single-channel micropipettes, bottle top dispensers, etc. Find what you need on our website!